Sector Motion and control technologies

Company Parker Hannifin

Employees 55,000

Main challenges

- Valves of high complexity and individually configurable sections with interdependencies

- Valve configurations that live over time and are affected by design changes

- Many customer-specific documents such as CAD, hydraulic diagrams and spare parts lists

- The choice of the right spool is complicated and needs to be combined with simulation data

Division Marketing Manager

Leif Johansson

We have had a close collaboration with In-process (the company behind Combinum CPQ) for many years and are very satisfied. Together, we have developed a first-class configurator that is an important sales tool and is highly appreciated by our customers and internally within Parker. In-process competence, the ability to understand our processes and needs and fast service are strengths that we place great value on.

The company

Parker Hannifin

Parker is a world leader in motion and control technology and provides precision solutions for mobile and industrial applications as well as for the aerospace industry. Parker is everywhere there is movement.

Combinum is used by two of Parker's mobile hydraulics divisions – one in Europe and one in the USA. The main area of use is for configuration of section-built directional valves.

The project

Background

Parker in Borås was early on with product configuration and introduced a configurator for its directional valves already in the 90s. When this Windows-based configurator needed to be replaced, several solutions were tried before the choice fell on Combinum. Decisive was Combinum's capacity to handle configurations in configurations corresponding to a valve built of sections.

The project

Challenges

Parker's sectional directional valves have a high degree of complexity and consist of sections that are individually configured to each control a function of the application such as a cylinder for an axial movement or a hydraulic motor for a rotation. The valve sections are affected both by selections that apply to the entire valve and by selections of surrounding sections, which increases the requirements on the configurator.

A configured valve can live for many years with repeat orders from OEMs. This means that design changes need to be introduced through BOM updates even for existing valve configurations.

Hydraulic schematics are used to describe the logical operation of a hydraulic system, but for the directional valves, the schematic often becomes unique for each configuration, which is why automation is needed. Other historically labor-intensive aspects were providing customer-specific CAD models, drawings and parts lists.

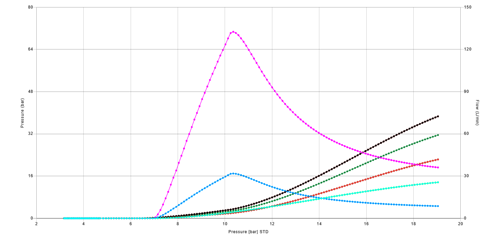

For a directional valve, the spool is the most important link between the operator's actuation via a lever device and the movement of the controlled function. The choice of spool is central to the optimal function of a valve, but the choice of spool must be made in context and depends, among other things, on the selected compensator. In order to give the seller and the customer the best basis for choosing a spool, after an initial filtering, curves are needed that describe the characteristics of different spools.

The project

Solutions

Configuration models have been built for valves with underlying configuration models for sections. Dependencies between valve and sections are mainly handled via inheritance of parameters from the valve to its sections. To handle dependencies between adjacent sections, rules have been created using functions that can read the values of "sibling configurations".

An integration has been built to Parker's ERP system where new valves are automatically posted as parts with associated bills of materials that have been generated by Combinum. Because the items that Combinum selects can be likened to bags of items, many design changes can be made directly in the ERP system, but sometimes changes need to be made at a higher level in the structure. For this, a batch function has been created that updates the ERP system with changed parts lists for the affected valves.

The hydraulic diagrams are dynamically generated based on the selections made and displayed in the browser using Combinum's 2D visualization. To accomplish this, Parker has built a library of schematic symbols. Placement and occurrence of symbols in the diagram is controlled via formulas and rules in a hierarchical graphic structure.

CAD models and drawings are created in Autodesk Design Automation via an integration where Combinum initiates and controls the generation of the CAD geometry via a web service.

The spools characteristics are presented to the user as curves and a range of different data can be presented. The source of the curves is a simulation database, but the spool curves are recalculated based on the valve section configuration.